Our automotive specialists have been involved in all aspects of noise, vibration and harshness (NVH) for over 40 years. With in-depth knowledge of automotive engineering, we are well placed to solve NVH problems and to identify ways to refine prototype or production engines, vehicles or components.

We use state-of-the-art design and development test facilities, including an advanced experimental rig (known as the ‘Banger Rig’) that enables us to measure an engine structure’s response to combustion force in a non-running engine.

Services range from noise and vibration measurements to more advanced modelling and the development of test methods and prediction techniques. For example, we can help with:

- intake, exhaust and silencer design and optimisation

- optimisation of engine cover design

- propagation of noise and vibration through engine structures

- active noise and vibration control

- setting targets for engine and vehicle noise and future designs to meet customer expectations

- subjective assessments of vehicles, engines and components

- noise reduction of seat motors, pumps and other secondary sources in luxury vehicles

- effects of engine, exhaust and tyre patch transfer functions on exterior and internal noise

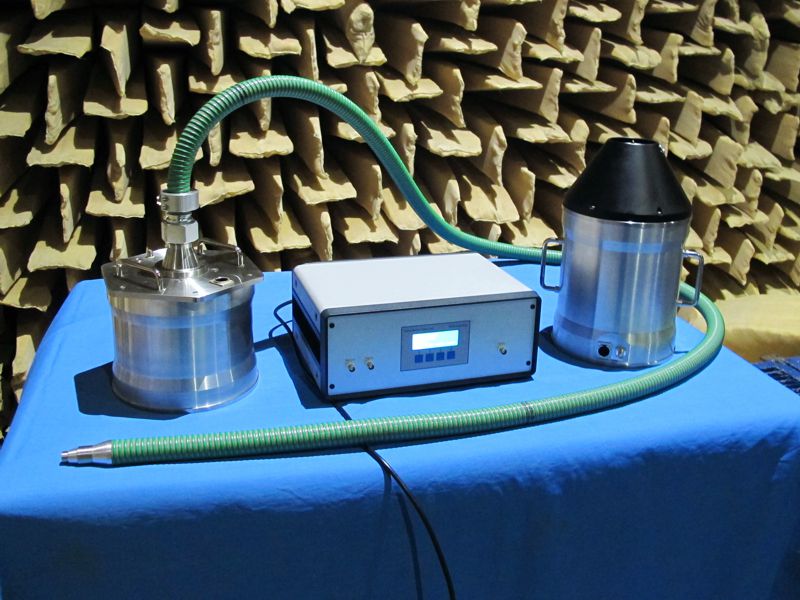

Our custom-built omni-directional sound sources are used by automotive companies all over the world.

We also offer bespoke short courses on noise and vibration for automotive professionals.